Our refrigeration and air conditioning test facilities support performance assessment, test procedure development, and research and development for next-generation equipment.

Performance Assessment

We test existing products to fully assess their performance using federal and industry testing standards. We evaluate and describe why product performance may not meet the stated technical specifications, including design review.

Test Procedure Development

We support development of industry test standards and develop new testing protocols and test methods that minimize burden while fully accounting for advanced product designs whose benefits may not be currently captured by existing test procedures. This includes creating new test protocols for prototype, integrated, or combination equipment for iterative research and development.

Research and Development

We research and assess next-generation product designs and provide guidance on performance optimization. We develop and fabricate prototypes in-house based on state-of-the-art research and practices to test the viability of advanced product design, system integrations, and automated control software.

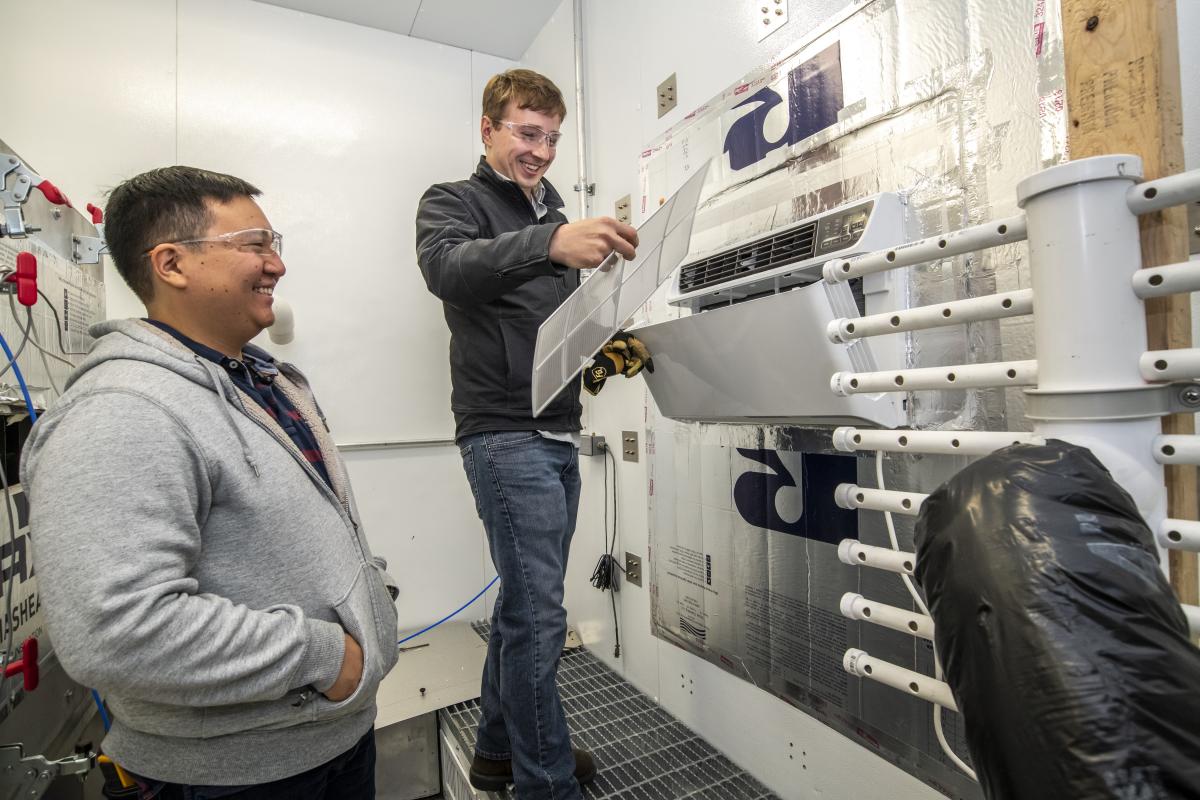

Balanced Ambient Calorimeter Test Chamber

The Balanced Ambient Calorimeter Test Chamber's primary purpose is to evaluate the performance of room air conditioners (split, window, or wall-type), packaged terminal air conditioners and packaged terminal heat pumps in the cooling capacity range of 6,000 to 42,000 Btu/h (½ to 3 ½ rated tons). It consists of side-by-side indoor and outdoor chambers with temperature, humidity, and airflow controlled independently. Both the indoor room and the outdoor room are surrounded by an annular space which independently maintains the same temperature and humidity as the rooms it surrounds.

The Balanced Ambient Calorimeter Test Chamber's primary purpose is to evaluate the performance of room air conditioners (split, window, or wall-type), packaged terminal air conditioners and packaged terminal heat pumps in the cooling capacity range of 6,000 to 42,000 Btu/h (½ to 3 ½ rated tons). It consists of side-by-side indoor and outdoor chambers with temperature, humidity, and airflow controlled independently. Both the indoor room and the outdoor room are surrounded by an annular space which independently maintains the same temperature and humidity as the rooms it surrounds.

The Test Chamber is designed to maintain a single set of operating conditions and is able to maintain conditions within the following dry bulb and web bulb temperature ranges:

Indoor = 45°F to 100°F DB; 43°F to 79°F WB

Outdoor = 10°F to 120°F DB; 40°F to 81°F WB

Psychrometric Test Chamber

The Psychrometric Test Chamber's primary purpose is to evaluate the performance of central air conditioners and heat pumps with cooling capacity in the range of 6,000 to 90,000 Btu/h (0.5 to 7.5 rated tons), and with heating capacity in the range of 6,000 to 60,000 (0.5 to 5 ton rated). It consists of side-by-side indoor and outdoor chambers with temperature, humidity, and airflow controlled independently.

The Psychrometric Test Chamber's primary purpose is to evaluate the performance of central air conditioners and heat pumps with cooling capacity in the range of 6,000 to 90,000 Btu/h (0.5 to 7.5 rated tons), and with heating capacity in the range of 6,000 to 60,000 (0.5 to 5 ton rated). It consists of side-by-side indoor and outdoor chambers with temperature, humidity, and airflow controlled independently.

The Test Chamber is designed to maintain a single set of operating conditions and is able to maintain conditions within the following dry bulb and web bulb temperature ranges:

Indoor = 45°F to 100°F DB; 43°F to 85°F WB

Outdoor = -20°F to 120°F DB; 35°F to 90.5°F WB

Refrigeration Test Chamber

The Refrigeration Test Chamber's primary purpose is to evaluate the performance of commercial and residential refrigerators, freezers, wine chillers, ice makers, and other refrigeration products. It is a temperature- and humidity-controlled environmental room that provides controlled environmental conditions.

The Refrigeration Test Chamber's primary purpose is to evaluate the performance of commercial and residential refrigerators, freezers, wine chillers, ice makers, and other refrigeration products. It is a temperature- and humidity-controlled environmental room that provides controlled environmental conditions.

The test chamber is designed to maintain a single point operating condition and is able to maintain dry-bulb temperatures in the range of 40°F to 120°F and humidity conditions in the range of 30% to 95%. It has the capability of testing four refrigeration units simultaneously at a single operating condition.